November 2nd, 5h

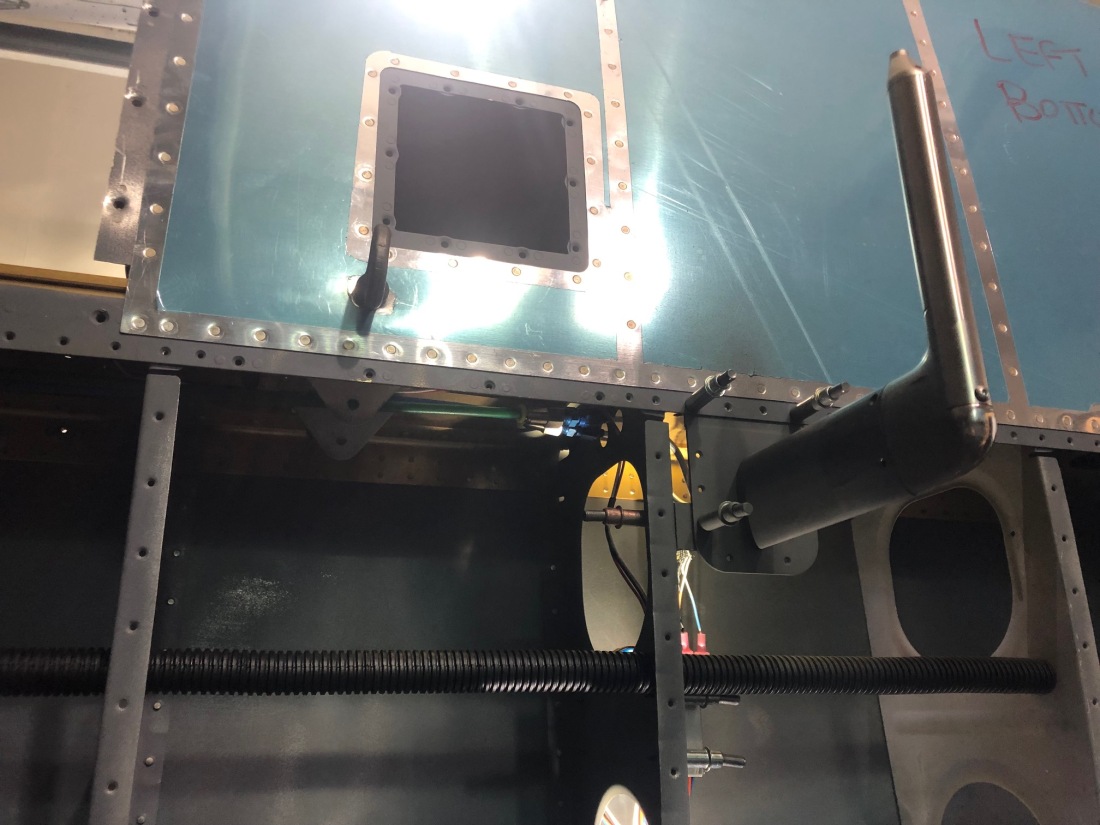

I continued on the prep for the wing riveting. So, I finish all the pitot/AoA probe wiring:

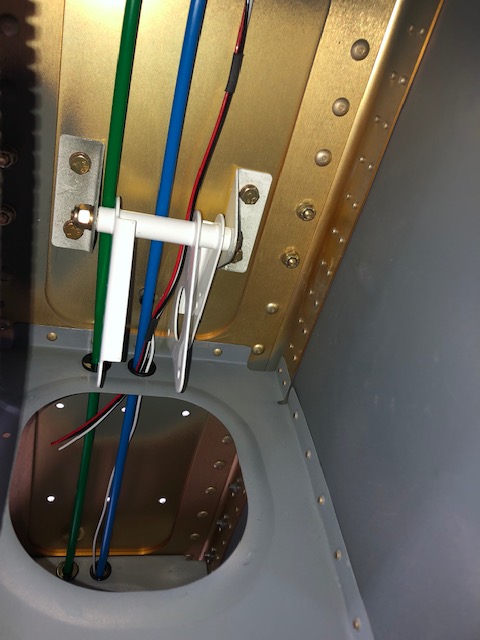

- Attaching the wires from the probe to the controller with zip-ties and zip-tie attachments that I glued with E6000 to the control unit.

- Extending the wires from the control unit by using 20 gauge wire of the same color and butt connectors

- Applying a wire protection for all the pitot/AoA wires, as well as the stall horn wire.

I also looked into attaching the pitot probe to the must with screw, but I had some trouble with tapping the holes. I am consulting with Dynon on that, and my current plan is to fill those holes with JB weld and to make new ones.